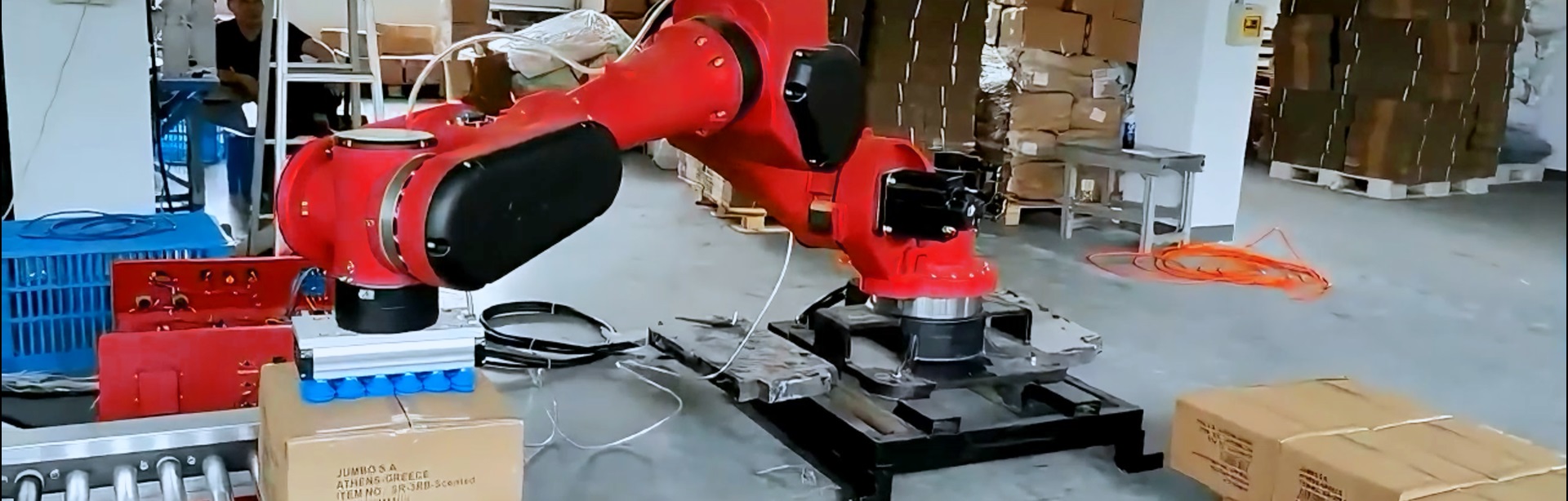

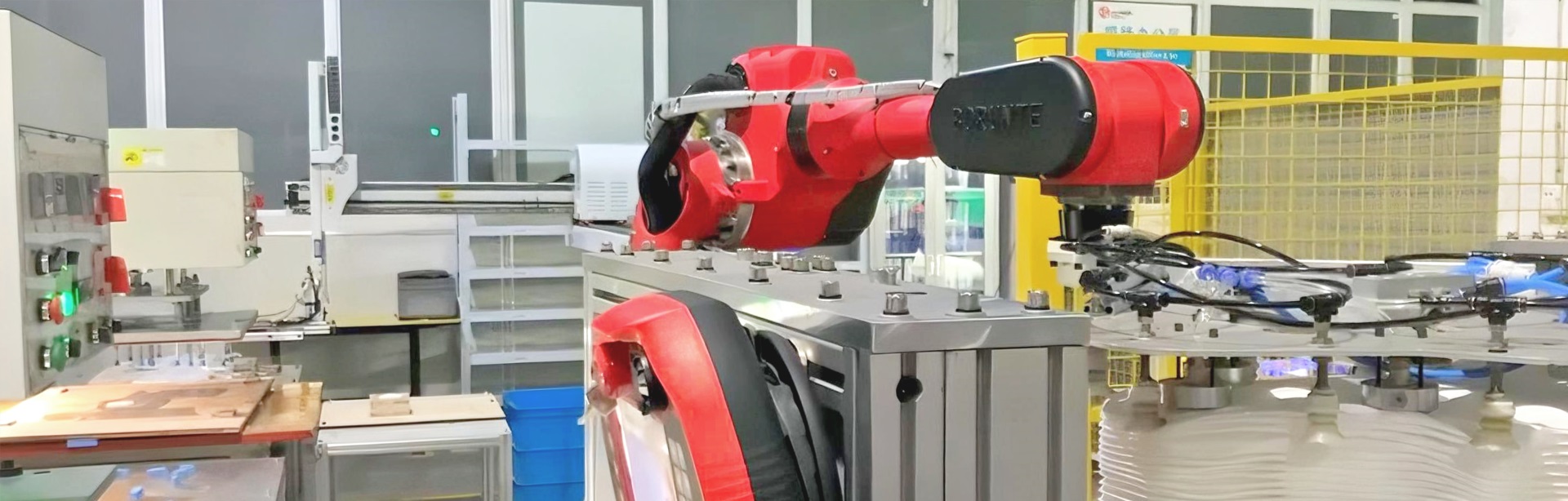

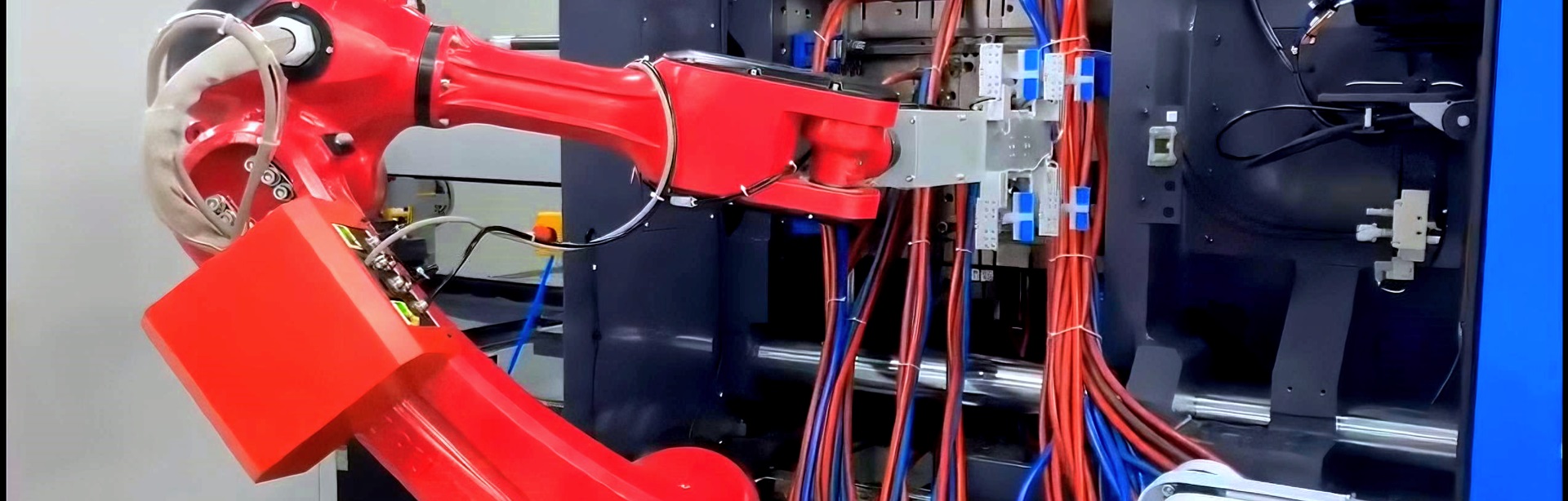

BRTIRBR2260A type robot is a six-axis robot developed by BORUNTE. It has a maximum load of 60kg and a arm span of 2200mm. The shape of the robot is compact, and each joint is equipped with a high-precision reducer. The high-speed joint speed can flexibly carry out sheet metal handling and sheet metal bending. The protection grade reaches IP54 at the wrist and IP40 at the body. The repeat positioning accuracy is ±0.1mm.

Accurate Positioning

Fast

Long Service Life

Low Failure Rate

Reduce Labor

Telecommunication

|

Item |

Range |

Max speed |

||

|

Arm |

J1 |

±160° |

118°/s |

|

|

J2 |

-110°/+50° |

84°/s |

||

|

J3 |

-60°/+195° |

108°/s |

||

|

Wrist |

J4 |

±180° |

204°/s |

|

|

J5 |

±125° |

170°/s |

||

|

J6 |

±360° |

174°/s |

||

|

|

||||

|

Arm Length (mm) |

Loading Ability (kg) |

Repeated Positioning Accuracy (mm) |

Power Source (kVA) |

Weight (kg) |

|

2200 |

60 |

±0.1 |

8.44 |

750 |

Four advantages of industrial bending robot:

Good flexibility :

1. Large activity radius and good flexibility.

2. It can realize the multi-angle metal sheet bending applications.

3. Long arm length and strong loading ability.

Improve bending quality and material utilization rate:

1.Fixed robot bending process with low bending failure rate

2.Robot bending produces high-quality products, reducing manual labor effort

Easy to operate and maintain :

1. six axis bending robot can be programmed offline, greatly reducing the on-site debugging time.

2. Plug in structure and modular design can realize rapid installation and replacement of components, greatly reducing maintenance time.

3. All parts are accessible for maintenance.

Inspection of lubricating oil

1.Please check the amount of iron powder in the reducer's lubricating oil every 5,000 hours, or once a year (for loading and unloading reasons, every 2500 hours, or once every six months). Please get in touch with our service center if replacing the lubricating oil or reducer is essential when it exceeds the standard value.

2.Before installation, sealing tape must be placed around the lubricating oil pipe joint and the hole plug in order to stop oil leakage when maintenance or refueling is finished. Use of a lubricating oil gun with adjustable fuel dosage is required. When an oil gun that can specify the quantity of oil is not feasible to create, the amount of oil can be verified by calculating the difference between the weight of the lubricating oil before and after the oil is applied.

3.The lubricating oil may be expelled at the time the manhole screw stopper is removed shortly after the robot has stopped when the internal pressure increases.

-

transport

-

stamping

-

Injection molding

-

Polish

Products categories

BORUNTE and BORUNTE integrators

In the BORUNTE ecosystem, BORUNTE is responsible for the R&D, production, and sales of robots and manipulators. BORUNTE integrators utilize their industry or field advantages to provide terminal application design, integration, and after-sales service for the BORUNTE products they sell. BORUNTE and BORUNTE integrators fulfill their respective responsibilities and are independent of each other, working together to promote the bright future of BORUNTE.

-

-

-

Top